Automatic Sieving Machines: Revolutionizing Material Separation for Efficiency and Precision in Industrial Processes

Introduction

Automated sieving machines are transforming industrial processes by offering faster, more efficient, and precise material separation. These machines are essential for industries such as mining, pharmaceuticals, food processing, and chemicals, where the need for fine material classification is critical. They work by separating materials based on size, ensuring that only particles of the desired dimensions pass through, while larger particles are retained for further processing.

The benefits of automatic sieving machines are numerous, from increased productivity to improved consistency in the final product and with advancements in automation technology, these machines now provide solutions that minimize human intervention, reduce errors, and maximize operational efficiency.

The significance of automated sieving machines cannot be overstated. They represent a leap forward in material handling and processing, offering a more streamlined and reliable approach compared to traditional manual sieving methods. Whether you’re looking to improve the throughput of your operations or reduce the likelihood of contamination, an automated sieving system provides the ideal solution. In this article, we’ll explore how automated sieving machines work, the different types available, their benefits, and why they are indispensable in modern manufacturing processes. Let’s dive into the world of automated sieving and see how it can elevate your production line.

How Automated Sieving Machines Work

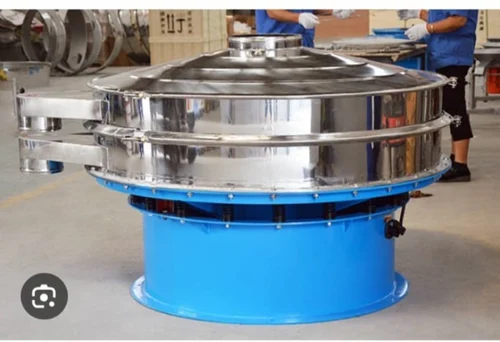

Automated sieving machines utilize a series of screens or sieves of varying mesh sizes, which are arranged in layers or placed one above the other. The material is fed into the machine, which vibrates or agitates the particles to promote the movement of finer particles through the mesh, while larger particles remain on top. This process is repeated for each layer, with each sieve separating particles into different sizes.

The automation aspect comes into play with the integration of motors, sensors, and computerized controls that monitor and regulate the sieving process. The machine can automatically adjust its settings, such as the vibration frequency, speed, or screen mesh size, depending on the material being processed. This means the operator doesn’t have to constantly monitor the sieving process, and the machine can continue to operate with minimal human intervention.

See also: The Healing Power of Plushies: Comfort in Times of Need

Types of Automated Sieving Machines

Automated sieving machines come in various designs, each tailored to specific types of material processing. Some of the most common types include:

- Vibrating Sieves:

Vibrating sieving machines are among the most popular types, utilizing vibratory motion to agitate the material and allow finer particles to pass through the mesh. These machines are versatile and can handle a wide range of materials, from powders to granular substances. They are typically used in industries like food processing, chemicals, and pharmaceuticals. - Rotary Sieves:

Rotary sieves are used for larger volumes of material. They use a rotating drum to separate particles, often employed in industries that require high throughput, such as mining and aggregates. These machines can handle both dry and wet materials, making them adaptable to various processing conditions. - Air Classifiers:

Air classifiers use air pressure to separate materials by size. This type of automated sieving machine is commonly used in fine powder processing, such as in the pharmaceutical and food industries. By controlling airflow, air classifiers can precisely separate very fine materials that are difficult to sieve using traditional methods. - Ultrasonic Sieves:

Ultrasonic sieving machines are equipped with high-frequency sound waves that vibrate the sieve mesh, helping to break down clumps and improve the separation of fine particles. This type is particularly useful when dealing with sticky or difficult-to-sieve materials, such as those found in the chemical or food industries.

Benefits of Automated Sieving Machines

The implementation of automated sieving machines brings a multitude of advantages to industries looking to improve efficiency, productivity, and quality control. These benefits include:

- Increased Efficiency and Speed:

Automated sieving machines can process large quantities of material in a short amount of time. Unlike manual sieving, which is labor-intensive and time-consuming, automated systems continuously operate at a fast pace, dramatically reducing processing time and increasing throughput. This is particularly beneficial for large-scale production lines. - Consistency and Precision:

Automation ensures that each sieving cycle is performed with the same settings, leading to more consistent results. The precise separation of materials based on their size minimizes the chances of human error, guaranteeing that each batch meets the required standards. This is especially important in industries like pharmaceuticals and food, where uniformity is key. - Reduced Labor Costs:

Since automated sieving machines require minimal human intervention, companies can reduce labor costs by replacing manual sieving tasks. Workers can focus on other important tasks while the machine operates independently. Additionally, automated systems often require less maintenance and fewer repairs, contributing to cost savings in the long run. - Improved Product Quality:

The ability to accurately separate particles based on size leads to higher product quality. For instance, in the food industry, automated sieving ensures that ingredients are consistently sized, enhancing the texture and appearance of the final product. In pharmaceuticals, accurate sieving ensures that active ingredients are evenly distributed for optimal efficacy. - Customization and Flexibility:

Automated sieving machines can be tailored to meet the specific needs of different industries. Whether the material is dry, wet, granular, or powdery, the machine can be configured to optimize performance. Additionally, the settings can be adjusted to handle materials with varying properties, ensuring flexibility across different processes.

Applications of Automated Sieving Machines

Automated sieving machines are used in a wide range of industries, including:

- Pharmaceuticals: Automated sieving ensures that powders and active ingredients are evenly distributed, leading to more consistent tablets and capsules.

- Food Processing: Sieving is crucial for removing contaminants and ensuring the quality of ingredients such as flour, sugar, and spices.

- Chemicals and Plastics: In the production of chemicals and plastics, sieving is used to separate raw materials, ensuring that only the appropriate particle sizes are used in the manufacturing process.

- Mining and Aggregate: Automated sieving machines are used to separate ores, minerals, and other materials by size, which is essential in mining and construction.

- Cosmetics: Sieving is used to refine powders, ensuring a smooth texture in products like makeup, creams, and lotions.

Choosing the Right Automated Sieving Machine

When selecting an automated sieving machine for your business, there are several factors to consider:

- Material Type:

Different materials require different sieving machines. It’s important to choose a machine that is capable of handling the specific type of material you are processing, whether it’s a fine powder or a coarse granular substance. - Throughput Requirements:

Consider how much material needs to be processed in a given time. Machines with higher throughput capabilities are ideal for industries with large-scale production needs, while smaller systems are more suitable for batch processing or specialty applications. - Machine Features:

Look for machines with features such as adjustable vibration speeds, easy cleaning mechanisms, and customizable sieve sizes. These features can enhance the flexibility and efficiency of the sieving process. - Budget:

Automated sieving machines come in a wide range of prices. It’s important to balance your budget with the performance and features you require. Investing in a high-quality machine can result in long-term cost savings by increasing efficiency and reducing maintenance needs.

Conclusion

Automated sieving machines are an indispensable tool in modern industrial processes, offering significant advantages over manual sieving methods. They enhance efficiency, precision, and consistency, making them a must-have in industries such as pharmaceuticals, food processing, mining, and chemicals. By automating the sieving process, businesses can reduce labor costs, improve product quality, and optimize their operations. Whether you’re looking to scale your production or improve the accuracy of material separation, investing in an automated sieving machine is a wise decision for any business looking to stay competitive in today’s fast-paced industrial landscape.